Manufacturing Equipments Advanced Production Site

In Recent Years, The Trend In Industry Is To Move Towards Automatic Means Of Production, Allowing High-Quality Goods To Be Made Efficiently With A Higher Production Capacity.

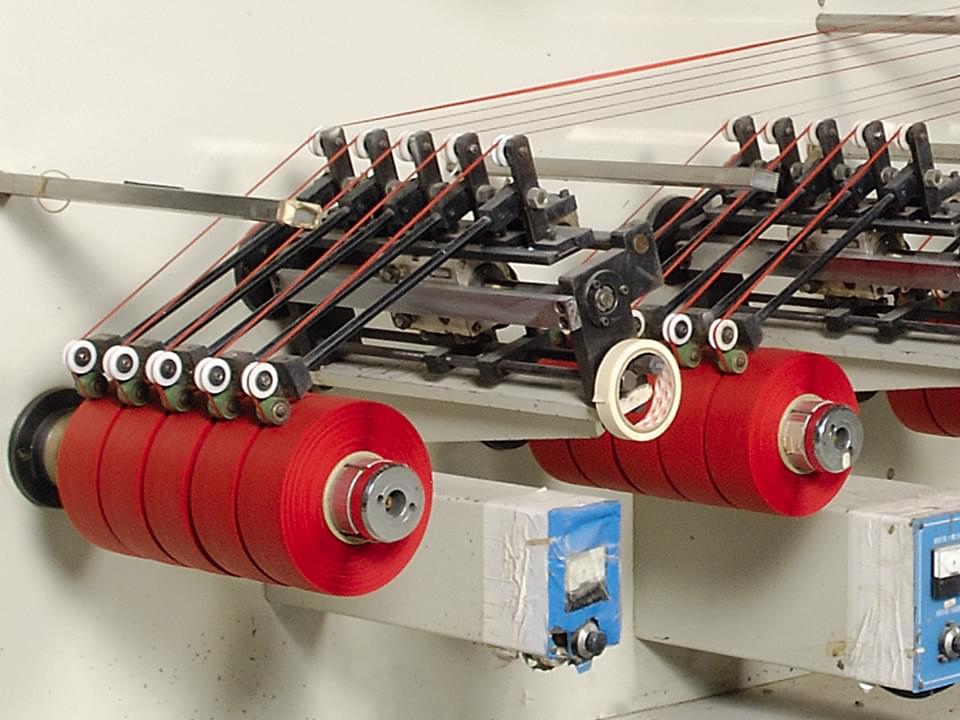

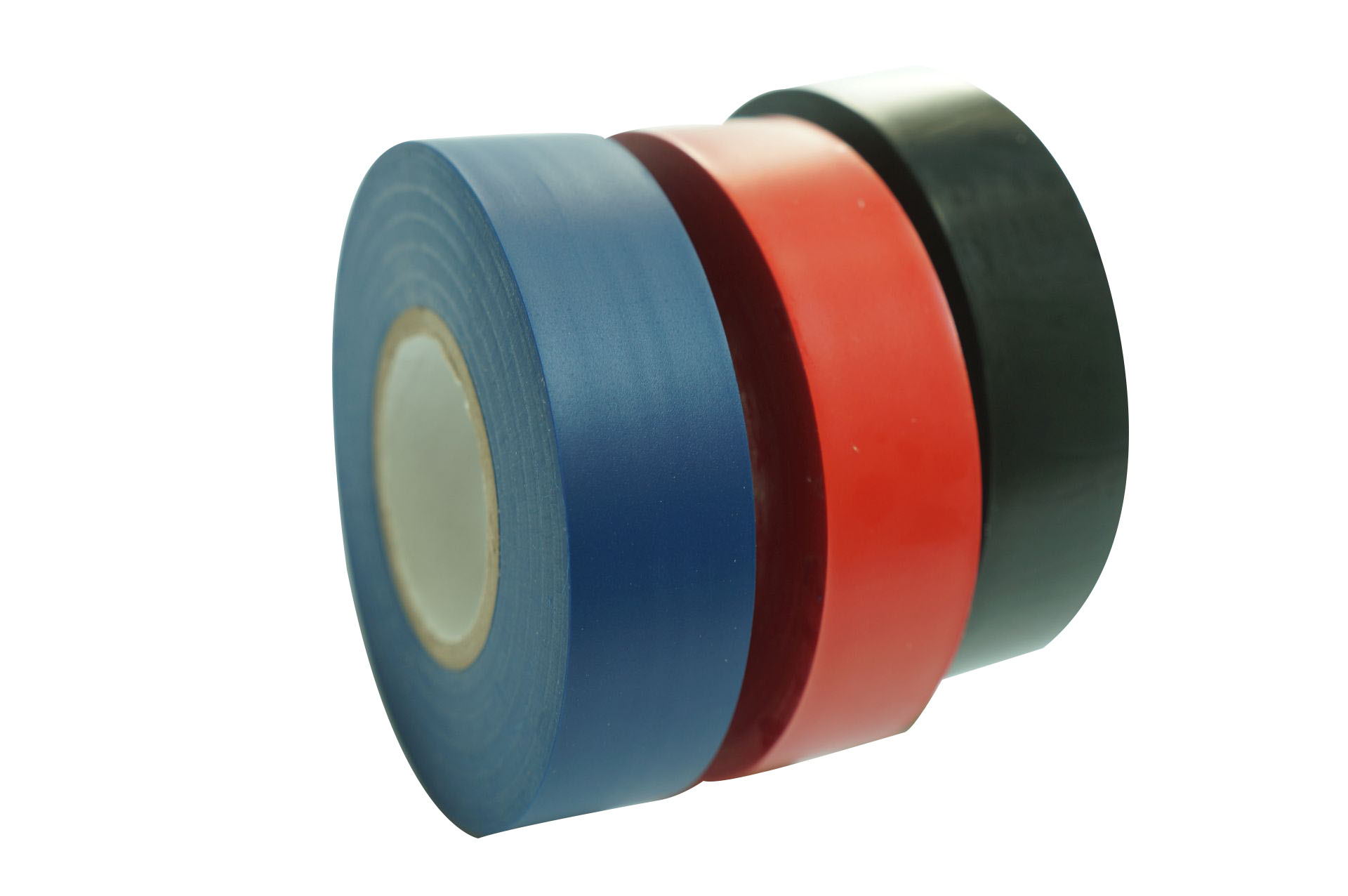

SPIRIT Continually Improves The Design Of Its Existing Machines And Research And Develops New Models In Order To Satisfy The Needs Of Industry Better. SPIRIT Has Two Coating Machine Designed In Accordance With The Different Adhesive Formula That SPIRIT Produces. They Are Dedicated Machines That Produce High Quality Masking Tape And PVC Tape.

They Are Equipped With Sections For The Adhesive Vulcanization As Well As A Metering And Mixing System For Adhesive Cross-Linking Agent To Be Able To Produce Adhesive Tape Jumbo Rolls For High Temperature. The Working Width Of The Coating Machine Is Up To 1600mm And The Mechanical Speed Can Up To 150m/Min. Also, SPIRIT Has Different Converting System Machines For SPECIALITY TAPES.